Artificial Intelligence is an umbrella term that covers several specific technologies. In this post, we will explore machine vision (MV) vs. computer vision (CV). They both involve the ingestion and interpretation of visual inputs, so it’s important to understand the strengths, limitations, and best use case scenarios of these overlapping technologies.

The Beginning of Computer Vision

Researchers began developing computer-enabled vision technologies as early as the 1950s, beginning with simple two-dimensional imaging for statistical pattern recognition. It wasn’t until 1978, when researchers at the MIT AI Lab developed a bottom-up approach to extrapolating 3D models from 2D computer-created “sketches” that CV’s practical applications became obvious. Image recognition technologies have splintered into different categories by general use case since then.

Machine Vision vs. Computer Vision – Commonalities

Both computer vision and machine vision use image capture and analysis to perform tasks with speed and accuracy human eyes can’t match. With this in mind, it’s probably more productive to describe these closely related technologies by their commonalities—distinguishing them by their specific use cases rather than their differences.

Computer vision and machine vision systems share most of the same components and requirements:

- An imaging device containing an image sensor and a lens

- An image capture board or frame grabber may be used (in some digital cameras that use a modern interface, a frame grabber is not required)

- Application-appropriate lighting

- Software that processes the images via a computer or an internal system, as in many “smart” cameras

Machine Vision vs. Computer Vision – The Biggest Difference

So what’s the actual difference? Computer vision refers to automation of the capture and processing of images, with an emphasis on image analysis. In other words, CV’s goal is not only to see, but also to process and provide useful results based on the observation. Machine vision refers to the use of computer vision in industrial environments, making it a subcategory of computer vision.

Computer Vision in Action

Currently, computer vision is playing a growing role in many industries. In digital marketing, companies are beginning to use image recognition technologies to drive better ad placement and business outcomes. Thanks to the growing accuracy and efficiency of CV technologies, marketers can now bypass traditional demographic research (which can be problematic in light of data privacy concerns) and quickly and accurately comb through millions of online images. They can then place targeted marketing in the right context, in a fraction of the time it would take for a human to achieve the same result.

Additionally, a recent study shows that 59% of marketing agencies employing computer vision are using it to detect unsafe brand content online. There’s nothing like finding your client’s ad for an artisanal meat delivery service placed next to an article about an e-coli outbreak, right? Other trending use cases for CV showcased at the 2019 Consumer Electronics Summit (CES) included a wide range of autonomous vehicle applications, security and safety enablement, and more.

Machine Vision and the Smart Factory

The ability to visually identify issues like product defects and process inefficiencies is critical for manufacturers to constrain costs and driving high customer satisfaction. Since the ‘90s, machine vision systems have been installed in thousands of factories worldwide, where they are used to automate many essential QA and efficiency functions. With enhanced data-sharing capabilities and improved accuracy powered by innovative cloud technologies, the use of MV-driven systems in manufacturing has begun to accelerate. In North America in 2017, the sales of machine vision and robotic systems and components had a best-ever year, as financial transactions grew 14.6% over the previous year to $2.633 billion. Manufacturers are realizing that machine vision systems are an essential investment for meeting goals around quality, cost, and speed.

Machine Vision on the Production Line

Detecting defects and quickly mitigating the cause of those defects is an essential aspect of any manufacturing process. Companies have turned to machine vision solutions to proactively address the occurrence and root cause of defects. By installing cameras on the production line and training a machine learning model to identify the complex variables that define a good product vs. a bad product, it’s possible to identify defects in real time and determine where in the manufacturing process the defects are occurring so proactive steps can be taken.

Annotating a Machine Learning Model for Vision Technologies

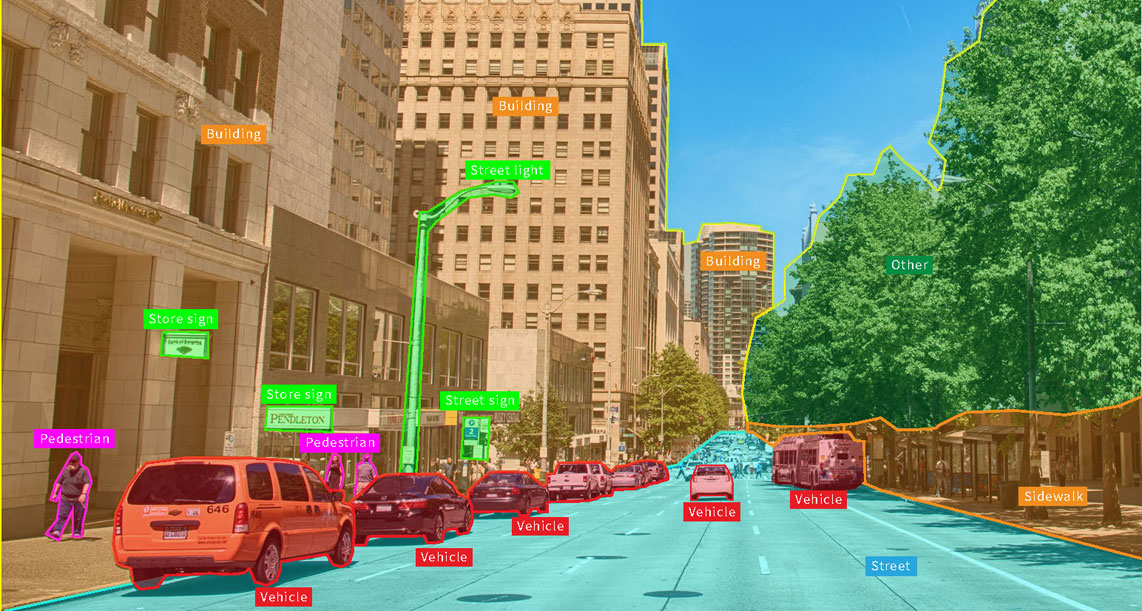

To achieve your computer or machine vision goals, you first need to train the machine learning models that make your vision system “intelligent.” And for your machine learning models to be accurate, you need high volumes of annotated data, specific to the solution you’re building. There are free, public-use datasets available that work well for testing algorithms or performing simple tasks, but for most real-world projects to succeed, specialized datasets are required to ensure they contain the right metadata. For example, implementing computer vision models within autonomous vehicles requires extensive image annotation to label people, traffic signals, cars, and other objects. Anything less than total precision is going to be a huge problem for a self-driving car.

Companies may choose to deploy an in-house annotation team to perform this type of image annotation, but it can be costly and divert valuable employees from working on core technology. Appen provides end-to-end data annotation services powered by thousands of skilled annotators, as well as experienced project managers who help companies determine the data needs for their project and help maintain high quality and throughput from annotators. Appen’s annotators remove the burden from your company and deliver high-quality datasets for training extremely accurate machine learning models.

Machine Vision vs. Computer Vision – Related Technologies with Distinct Use Cases

Although the line delineating machine vision vs. computer vision has blurred, both are best defined by their use cases. Computer vision is traditionally used to automate image processing, and machine vision is the application of computer vision in real-world interfaces, such as a factory line.

—

Looking for high-quality custom datasets for your computer vision or machine vision solution? Contact us to learn how Appen can help with image collection and annotation.